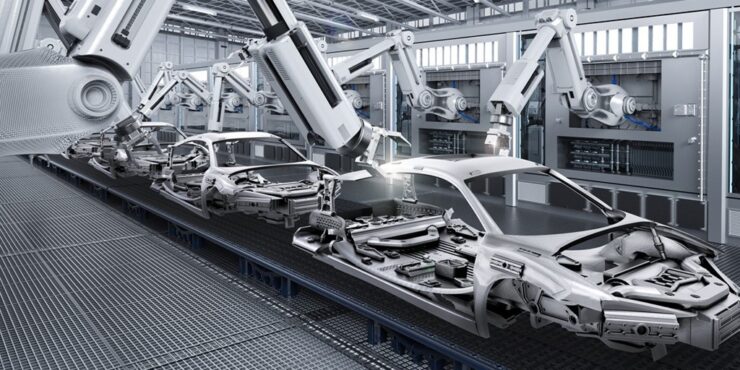

The vehicle-making industry has changed a lot in recent years. Nowadays, car producers put out more high-end products with modern tech. An aspect that helps is using machines and robots to help speed up tasks.

But the machines and robots rely on specific components to work. One component playing a central role is the linear actuator. We’ll be discussing how these motion devices help in this post.

How Linear Actuators Help With Automotive Assembly Line Automation

Linear actuators have many uses by car producers in assembly line automation. Below are four primary examples:

Material Joining

Cars consist of different parts joined to get the final product. Linear motion devices help make the joining process easier. The straight moment they create allows proper force and displacement applications. Also, their high speed and repeatability increase accuracy and control.

Car manufacturers use linear actuators for material joining in different areas. Examples include:

- Spot welding

- Riveting

- Clinching

- Adhesive bonding

Different types of linear motion devices work for these tasks. But most manufacturers rely on electric options.

End Effector Gripping

Assembly line automation during car making usually involves holding and handling various objects. This is end-effector gripping in a basic sense. The gripper system will need proper positioning, speed, and repeatability. By default, linear motion devices allow all these operations.

Here are some areas where linear motion devices help for end effector gripping:

- Front Module Assembly (FEM)

- Linear Module CLSM

- Soft and Smart Robotic Gripper

Besides helping them perform better, linear actuators also increase safety. Hence, there’s less risk of accidents during the assembly process.

Jig Setting

The jig-geo feature performs a crucial task. It holds different parts of the vehicle when being joined to another part. As a result, it needs high accuracy, which is one top benefit of linear actuators.

Another area these devices play out during jig setting is for body-in-white assembly. Such a process usually involves joining different parts of the car’s exterior. Linear actuators can help hold the parts for longer without affecting performance. A linear motion device will also help when creating automated designs.

Final Assembly

The final assembly stage can make or break a car. Usually, there’s a lot to do. But linear actuators make it easier.

These actuators can help when making the wiring harness. In particular, the device holds the car cables in place while the machines work. That way, there’s less clustering.

Furthermore, suppose the car needs transport to a different factory for final assembly. In that case, a linear actuator will help with the transfer unit. Also, it’ll help boost connections with other machines and sensors.

Advantages of Linear Actuators in Automotive Assembly Line Automation

When used in assembly line automation, linear actuators have many advantages. Here are some:

-

Flexibility

Already, it’s clear linear motion devices fit different tasks in assembling line automation. That defines flexibility. In other words, the devices are versatile. How is that possible? Well, linear actuators work by adjusting stroke length, speed, and force. It all depends on the application.

Hence, you can save money purchasing different motion systems using an actuator. All you need to do is reprogram the device to suit the task. Furthermore, some linear actuators work with remotes and other wireless control systems. With such options, operating the device becomes seamless.

-

Accuracy

Linear actuators reach exact and stable positions thanks to their high accuracy. In automotive assembly line automation, this increased accuracy ensures controls that require straight motion are more efficient. It provides less room for errors and waste. Also, the manufacturer will be able to produce vehicles customers can trust.

-

Speed

Speed plays a top role in assembly line automation. It ensures products are set up quickly, and linear motion devices help. They not only move rapidly in a straight line but also swiftly. 5 m/sec is the norm for these devices. But high-end options can reach up to 10 m/sec.

During assembly line automation, such high speeds offer many benefits. It’s helpful since the process usually involves simultaneous tasks in different stations. Quick operation means less time, which means lower cost and energy consumption.

-

Efficiency

Efficiency houses all other benefits, including flexibility, speed, and accuracy. The combination of all means a linear motion device works in a well-ordered manner. Irrespective of the automation task, the actuator can adapt to its conditions.

It’s worth mentioning that the design also helps. Most linear motion devices used in car parts assembly are electric, which makes them easy to manage and maintain. Also, there are some types that will fit about any product integration. Frigelli Automations provides more information about such linear actuators.

Opportunities for Linear Motion Devices in Automotive Assembly

While they already have many uses in car production assembly, there’s still room for actuators to do more. Here are some opportunities:

-

Environmental impact

Linear motion devices come in different types, including hydraulic, pneumatic, and electric. The first two use fluids and pressurized gas, respectively. As a result, they’re not much friendly to the environment. But electric options use a motor with less environmental impact.

Hence, car manufacturers can help the environment by using more electric motion devices. The good thing is that this is already the trend.

-

Industry 4.0

Linear actuators could play more critical roles in the fourth Industrial Revolution. The movement focuses on digital tech with smart control. Already, some linear motion devices use sensors and automated controllers. Adding more smart systems to boost operation can greatly benefit automotive assembly.

-

IoT Integration

If more linear motion devices connect with IoT tech, car manufacturers get better performance. This integration can help improve monitoring, control, and optimization applications. Also, it can boost the development of innovations in both the automotive and IoT industry.

Conclusion

Regarding automotive assembly line automation, linear actuators have many applications. Material joining, end effector gripping, and others in the post are only a few. Their speed, accuracy, flexibility, and efficiency benefits make these actuators reliable. Also, they could improve the automation process by taking advantage of available opportunities.